This is our first post using AI (ChatGPT – 3.5)! PLEASE NOTE that the post has not been fact-checked for accuracy, so the robot (aka chatbot, aka computer) might have made errors in the LLM text replies…

The first prompt was:

“The T.E.G. is a Thermoelectric Generator. Small amounts of current can be generated by sandwiching certain metal alloys in sequence at different temperatures and the heat exchanged through the alloy sandwich layers generates the electrical current. This is an evolving technology. What are the latest examples of TEG systems, and can they be scaled up to provide significant power for homes or industrial uses?”

ChatGPT 3.5 output the following in just a few seconds:

As of my last knowledge update in January 2022, thermoelectric generators (TEGs) have seen ongoing research and development to improve their efficiency and scalability. However, while advancements have been made, widespread deployment for powering homes or industrial uses has not yet been achieved. Here are some recent advancements and considerations regarding TEG systems:

Latest Examples of TEG Systems:

- Automotive Applications: TEGs have been explored for automotive applications to recover waste heat from internal combustion engines or exhaust systems. Some car manufacturers have experimented with TEGs to power auxiliary systems or improve fuel efficiency.

- Wearable Devices: Miniature TEGs have been developed to harness body heat and convert it into electrical energy for small electronic devices, such as wearable sensors or medical devices.

- Energy Harvesting: Research continues to focus on TEGs as part of energy harvesting systems in remote or low-power applications, such as sensors in IoT devices or in space missions.

- Industrial Waste Heat Recovery: Some industries are experimenting with TEGs to capture waste heat from various processes and convert it into electricity, enhancing overall energy efficiency.

Scalability for Homes or Industrial Uses:

While TEG technology has shown promise in various applications, scaling it up for significant power generation faces several challenges:

- Efficiency: Traditional TEGs have relatively low efficiency compared to other power generation methods. Improving efficiency remains a crucial area of research to make them viable for larger-scale applications.

- Cost and Materials: Materials used in TEGs can be expensive, limiting large-scale deployment. Finding cost-effective and scalable materials while maintaining performance is essential.

- Heat Differential Requirement: TEGs require a significant temperature difference between the hot and cold sides to generate electricity efficiently. Scaling up to provide substantial power for homes or industries would need a considerable heat source and sink, posing logistical challenges.

- System Integration and Engineering: Designing TEG systems at a larger scale for reliable and consistent power generation involves complex engineering and integration challenges.

- Market Viability: Even with advancements, the cost-effectiveness and competitiveness of TEGs compared to other established energy sources like solar, wind, or conventional power remain to be seen.

While TEG technology continues to evolve, significant hurdles must be addressed before it becomes a practical and cost-effective solution for powering homes or industrial-scale applications. Ongoing research aims to overcome these challenges, but widespread adoption for large-scale power generation may still be some years away. For the most recent developments, I recommend checking the latest scientific journals, industry reports, or research institutions actively working on TEG technology.

Second Prompt for Chat GTP 3.5: Are there any commercially available TEG products being offered for sale, as of January 2022?

ChatGPT: As of January 2022, there were some commercially available thermoelectric products on the market, albeit mostly in specialized applications or as components rather than standalone TEG systems designed for widespread use in homes or industrial settings. These products often target specific niche applications. Here are a few examples:

- Wearable Devices and Sensors: Some companies have developed small-scale thermoelectric generators incorporated into wearable devices or sensors for powering low-energy electronics. These are often used in specialized fields like healthcare, IoT, or military applications.

- Power Banks and Chargers: There were a few portable power banks or chargers available that utilized TEG technology to convert small temperature differentials into electrical power. These were typically designed for charging small electronic devices like smartphones or tablets.

- Remote Power Solutions: Certain companies offered thermoelectric modules or systems as components for remote power solutions, such as off-grid sensors, monitoring devices, or data loggers.

- Automotive Applications: Some automotive manufacturers explored using TEGs in vehicles to harness waste heat from engines or exhaust systems. However, these were more experimental and not widely available in consumer vehicles at the time.

While these products demonstrated the feasibility of using thermoelectric technology in various applications, they were often limited in power output and mainly suited for specific use cases due to the current limitations in efficiency, scalability, and cost.

For the most recent information on commercially available TEG products, including any advancements or new product releases since January 2022, I recommend checking with specialized manufacturers, technology news outlets, industry publications, or directly searching commercial platforms specializing in energy generation or electronic components. The field of thermoelectric technology is evolving, and there might have been new developments or product launches in this space since the beginning of 2022.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

The information above this line was provided by Chat GPT 3.5 in December of 2023, but as noted, the LLM was only trained on data up to January 2022, so there are already more than two years of development on this technology not covered in the article above.

The information and text below was generated by Gemini AI in August of 2024 (using the same two prompts as the ones used with Chat GPT, avove)…

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

The Thermoelectric Generator (TEG) technology has been evolving rapidly, with promising applications in various fields. Here are some recent examples and potential for scaling up:

Latest Examples:

- Waste Heat Recovery: TEGs are being used to capture and convert waste heat from industrial processes, vehicles, and data centers into electricity. For instance, companies like Alphabet (Google) are exploring TEGs to harness the heat generated by their massive data centers.

- Wearable Electronics: Flexible and lightweight TEGs are being integrated into wearable devices like smartwatches and fitness trackers to extend battery life or even eliminate the need for external batteries altogether.

- Internet of Things (IoT): TEGs are being used to power low-power IoT devices, enabling them to operate autonomously without the need for frequent battery replacements.

- Automotive Applications: TEGs are being explored for use in exhaust systems to recover waste heat and generate additional power, improving fuel efficiency.

Scaling up for Significant Power:

While TEGs have shown great potential, scaling them up to provide significant power for homes or industrial uses remains a challenge. Here are some factors limiting their current capabilities:

- Efficiency: The efficiency of TEGs is still relatively low compared to traditional power generation methods. This means that a large amount of heat needs to be generated to produce a significant amount of electricity.

- Cost: The materials used in TEGs can be expensive, especially for high-performance applications. Reducing the cost of TEG materials is essential for widespread adoption.

- Size and Weight: TEGs can be bulky and heavy, making them less suitable for certain applications. Developing smaller and lighter TEGs is a priority.

However, ongoing research and development efforts are addressing these challenges. Advances in materials science, manufacturing techniques, and system design are gradually improving the efficiency, cost-effectiveness, and scalability of TEGs.

Future Potential:

With continued advancements, TEGs could become a viable option for generating significant power in various applications. For example:

- Hybrid Power Systems: TEGs could be integrated with renewable energy sources like solar and wind to provide backup power or to optimize energy efficiency.

- Remote Power Generation: TEGs could be used to power remote locations where traditional grid connections are impractical or expensive.

- Industrial Processes: TEGs could be used to recover waste heat from industrial processes, reducing energy consumption and costs.

In conclusion, while TEGs are still in their early stages of development, they have the potential to become a valuable tool for sustainable and efficient power generation. As research and development progress, we can expect to see even more innovative applications and advancements in this promising technology.

Second Prompt for Gemeni: Are there any commercially available TEG products being offered for sale, as of today? Show drafts

Yes, there are commercially available TEG products on the market. Several companies specialize in manufacturing TEGs for various applications. Here are a few examples:

- TEGmart: Offers a range of TEG generators, including those powered by candles, wood stoves, and other heat sources.

- Custom Thermoelectric: Provides custom-designed TEGs for specific applications, such as waste heat recovery and power generation. Google Search found similar content, like this: Custom Thermoelectric specializes in custom made and “customized” TE devices designed to optimally fit a customer’s specific requirements. customthermoelectric.com

- Other companies: Many other companies, both large and small, offer TEGs for various industries and purposes.

Note: While TEGs are available, their commercial use is still relatively niche. The market is growing, but factors like efficiency, cost, and size limitations can influence their widespread adoption. It’s always recommended to research and compare different products and suppliers to find the best fit for your specific needs.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Information below this line was NOT generated by AI, but was largely copied from various (now likely outdated) articles and press releases about developments in TEG research from several years ago.

Thermoelectric Tubes:

Utilizing the Geothermal Heat to Solve the Energy Problem

Solar and wind power, currently the most common sources for renewable energy, generate amounts of electricity which can vary greatly depending on the time of day or the weather. This has led to the problem of persistently low utilization efficiency of power generating facilities. Geothermal energy generation technology, which uses heat from inside the earth or hot springs, is generating attention as a stable source of renewable energy. In particular, “heat exchange,” which can convert heat directly into electrical power, has received a lot of attention as one of environmentally friendly electricity generation technologies which achieves zero-emission of carbon dioxide.

The Idea to Turn the Pipe Itself into an Electric Generating Element

The “thermoelectric conversion element” converts heat into electricity utilizing the “Seebeck effect ” which produces voltage caused by a difference in temperature between both sides of a material. Without any moving parts like turbines, it is earning attention as an energy generating technology which emits no carbon dioxide.

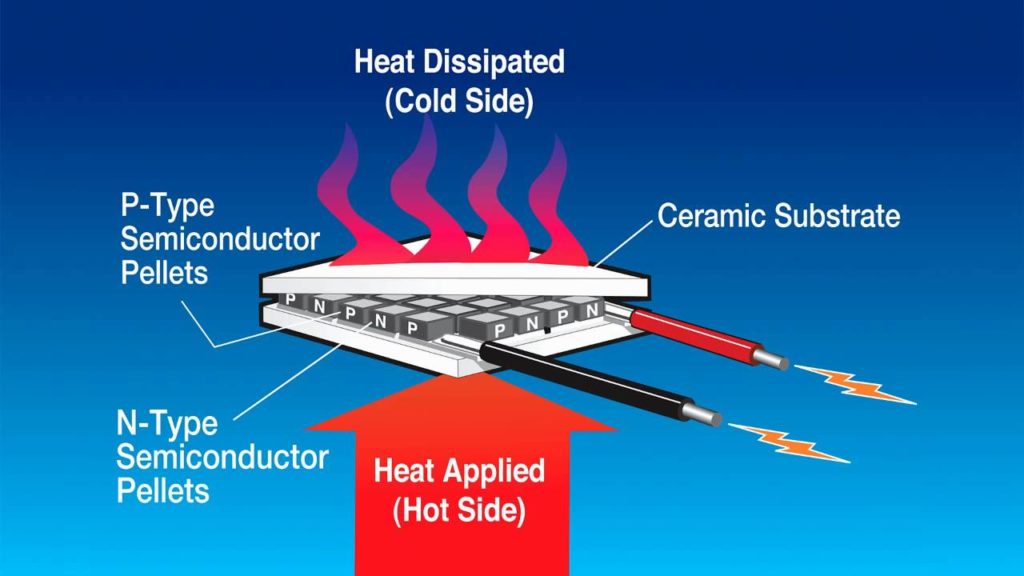

As shown in the diagram, conventional thermoelectric conversion elements are constructed to generate electricity by lining up the P-type and N-type thermoelectric conversion materials, connecting one side with metal, and the other side with an electrode attached to conducting wire. Because of its structure, this is called “π (pi) shape.” This structure is complicated and allows for a lot of heat loss to the thermoelectric conversion element, so it presented several challenges, including scaling it upward.

<Conventional Thermoelectric Generation Device>

Panasonic discovered that a periodic temperature distribution is generated in a device which causes a current flow perpendicular to the heat flow by a structure of tilted multilayer made of thermally-resistive thermoelectric materials and thermally-conductive materials. To make use of this effect for efficient electricity generation, Panasonic has invented a “thermoelectric tube” built with alternating layers of thermoelectric conversion materials and metals, utilizing the difference in temperature between the inside and outside of the tube to generate electricity.

<How a Thermoelectric Tube Works>

By running hot water through a tube placed in cold water, there is a heat flow from the inside of the tube to the outside; and because electricity runs along the length of the tube, the pipe itself conveying the hot water is able to be used as an electricity generating element. A thermoelectric tube of 10 cm in length enabled to generate 2.7 watts of electricity.

New Developments in Heat Flow Simulation Technology and Manufacturing Methods

Among these newly developed thermoelectric tubes, the characteristics of the power generated can vary greatly, depending on the shape of the tube and diagonal alignment of materials for heat flow. In order to maximize electricity generation, Panasonic has recently devised a technology to simulate the variables which affect electricity generation, such as the temperature and flow rate of the water sent through the tubes.

One issue which arose in the manufacture of the tubes is that of molding them into tube shape. The process of straightening or bending bismuth-tellurium, used as a thermoelectric conversion material, is quite difficult. But Panasonic worked out a way to first mold the thermoelectric conversion material and metal into conical rings of each material, and then stack them alternately to form tube shape. This technology achieves tilted multilayer structure of thermoelectric conversion material and metal with a high level of adhesion, and led to optimum generation characteristics which consistent with simulation results. Because the thermoelectric tubes themselves are able to generate electricity, we have come much closer to realizing a thermoelectric system which efficiently utilizes the heat inside the earth.

The Latest Trends

Panasonic has been continuing to develop the thermoelectric tubes, and has succeeded in efficiently converting electricity from a relatively low-temperature heat source, below 200°C.

In a project by NEDO (New Energy and Industrial Technology Development Organization) entitled “Research and Development Program for Innovative Energy Conservation Technology / Leading Research Project / Research and Development of Thermoelectric Devices for Independent System,” a verification test lasting over 200 hours has confirmed that the performance of electric power generation from 96°C hot waste water is comparable to approximately 4 times that of solar power generation converting into the installation area (*Based on comparison with the generation performance of solar panels (200W/m2) with a conversion efficiency of 20%). The result of this experiment has demonstrated the effectiveness of the power generation using unused low-temperature heat of below 100°C, previously considered unfit as a heat source for electricity generation. ,. This technology is expected to utilize unused heat for broad range of applications.

<Status of the Power Generation Verification Experiments at the Kyoto City Tohokubu Clean Centre>

(Left)View of experiment involving electricity generation equipment comprising three thermoelectric units

(Right)Internal composition of thermoelectric unit, and thermoelectric tube installed within

By utilizing several of these thermoelectric tubes to compose a thermoelectric unit, it is possible to use heat not just from the earth or from hot springs, but even unutilized heat sources which are commonly disposed of, such as hot waste water from factories.

———————————————-

Some day, when Panasonic makes these available, perhaps they can be effectively used at BBHSP to generate small amounts of electricity from the natural flows of hot mineral water. (???)